Finishing of Weldments and Fabrications

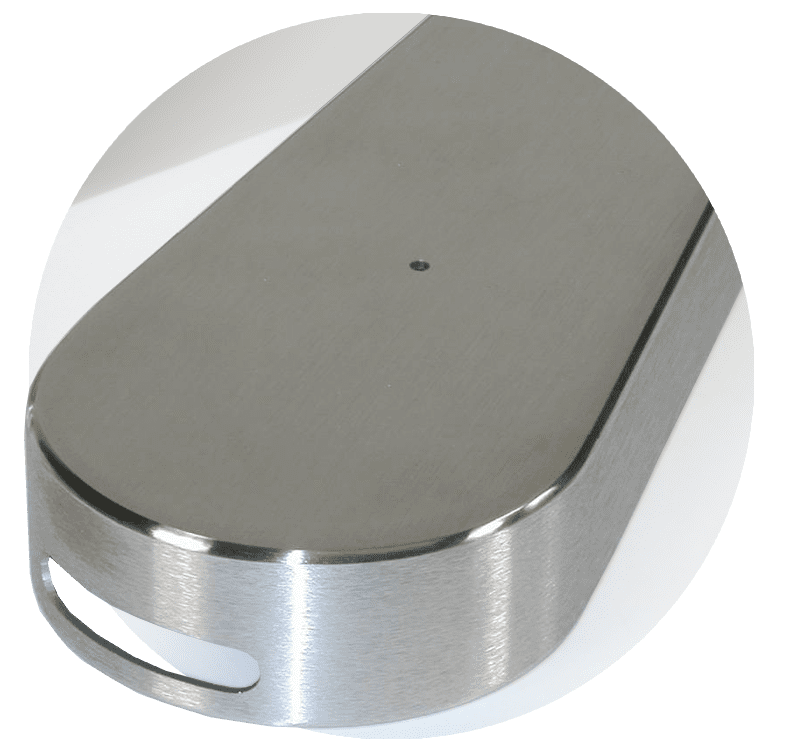

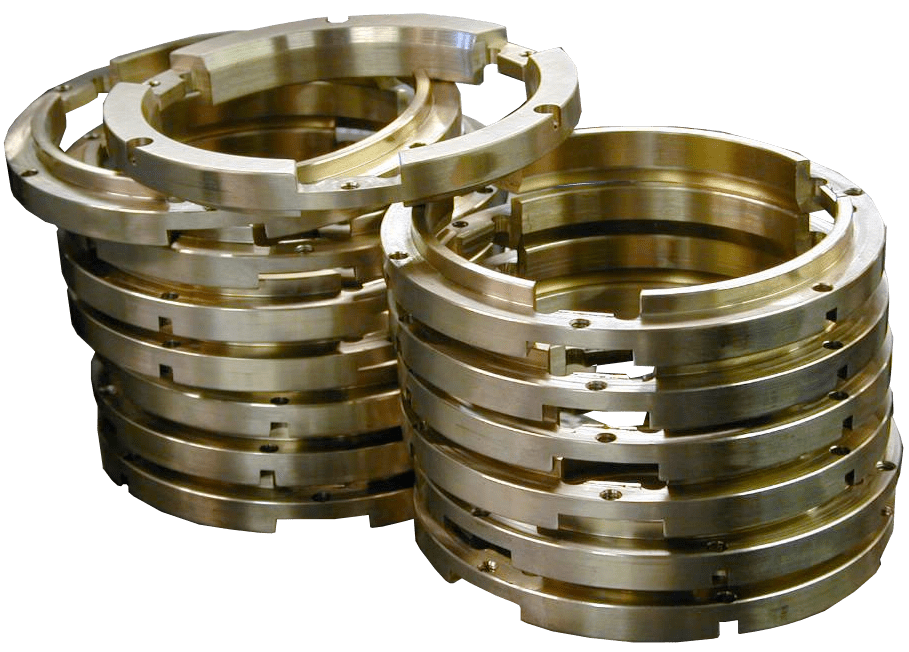

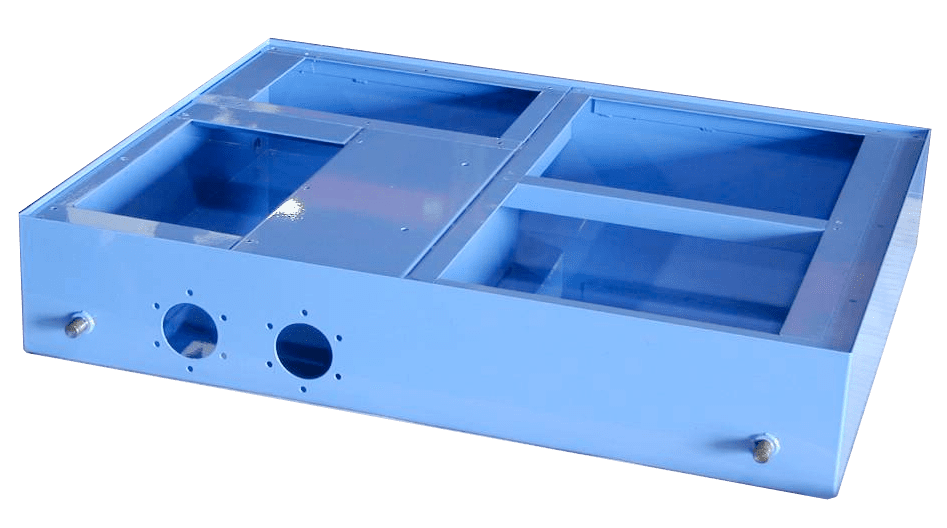

Metal parts deburring, grinding, and polishing

Our industrial metal finishing department is responsible for restoring the esthetic appearance of the metal fabrications and welded components. The process of deburring, grinding welds and restoring finishes includes the use of large equipment as well as small hand held grinders and polishers.

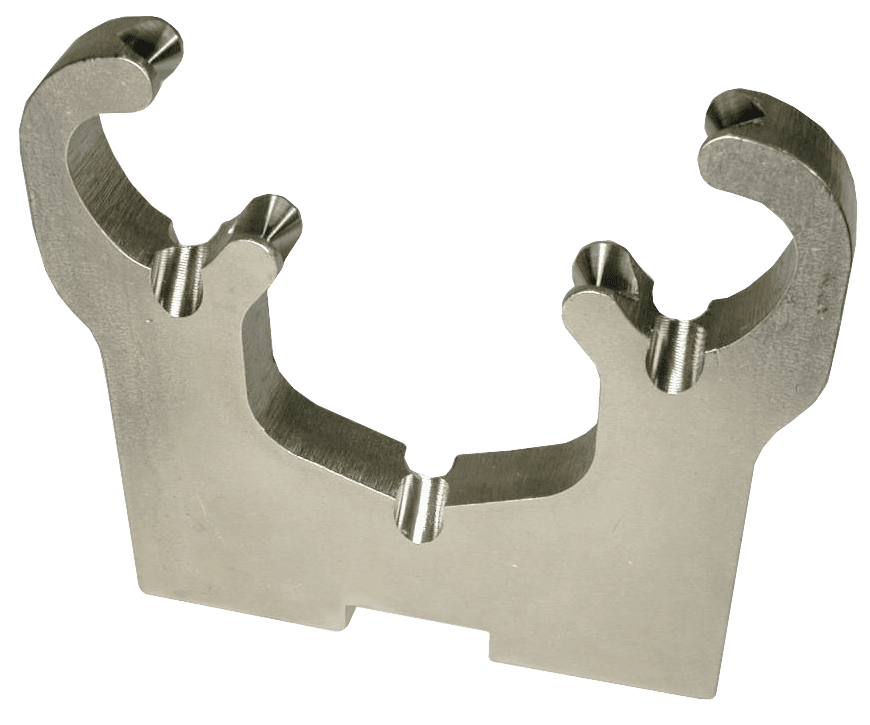

Stainless specialists

Specialists in stainless steel and mild steel parts manufacturing.

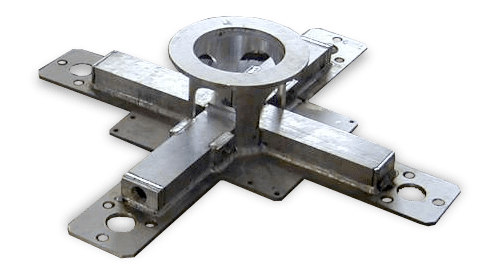

One-stop machine shop

Single, reliable source for high-quality parts. Comprehensive in-house capabilities.

Precision parts fabrication

Experienced craftsmanship using advanced technologies.

Fast Lead Times

Quick, accurate parts turn-around through flexible scheduling

Engineering solutions

Partnering to provide the best solution for your part design.

Our craftspersons smooth the welds and finish the project's surfaces according to a wide variety of needs and specifications. Utilizing their expertise, parts are finished by removing blemishes and imperfections in the part leaving a superior cosmetic finish appearance or in preparation for surface treatment. We’re experts in stainless steel finishes.

Abrasive media blasting is an excellent way to remove old paint, rust and to increase paint/powder adhesion. We use lead-free, soda-lime glass beads, which produce a uniform, clean, bright, satin finish, without dimensional change of the parts.

Thorough Process and Procedure Documentation

We want to be your manufacturing partner rather than just a parts supplier. To remain competitive in a global market, our customers are looking for partners that offer services above and beyond. All processes and procedures are documented.

Greater Cincinnati location

Batavia, OH 45103

U.S.A.

Give us a call

Contact us by email

Your form submission will be read immediately by Deltec Manufacturing Engineers.